A factory was under immense pressure to operate with greater speed, precision, and flexibility than ever before. As global supply chains grow increasingly complex, the owners wanted to implement more automation to maintain efficiency, reduce downtime, and meet rising customer expectations. They needed intelligent solutions that could seamlessly integrate with existing infrastructure while optimizing production processes.

The Evolution of Factory Automation

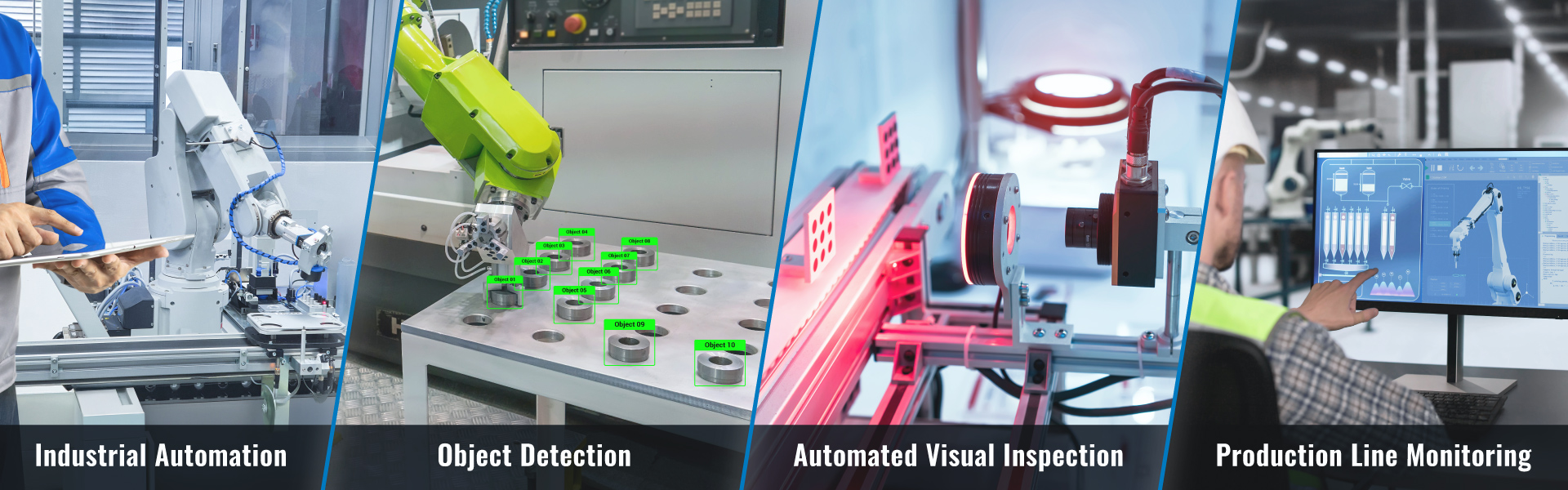

Gone are the days when factory automation meant rigid assembly lines and simple robotic arms. Today, intelligent automation systems harness AI-driven analytics, real-time monitoring, and edge computing to refine decision-making, minimize waste, and improve overall equipment effectiveness (OEE). These technologies not only keep production lines running smoothly but also provide critical insights that enable manufacturers to anticipate issues before they arise.

The transition to smart automation was crucial to meeting demand. The factory had struggled with bottlenecks in quality inspection, leading to rework and delays in shipping. By deploying VIA Intelligent Solutions that integrated advanced machine vision and edge computing, operators could analyze thousands of components per hour with pinpoint accuracy. Defective parts were flagged instantly, preventing defective products from making it further down the assembly line. Over time, data collected from these inspections also helped refine production techniques, reducing waste and improving yield rates.

Beyond quality control, automation played a key role in predictive maintenance. Sensors installed across key machinery continuously monitored vibration, temperature, and performance trends. Using real-time analytics, the system identified early signs of wear before they could lead to critical failures. This allowed maintenance teams to intervene proactively, replacing components before they broke down, eliminating unplanned downtime, and optimizing production efficiency.

Expanding Automation with Robotics in Harsh Environments

Robotic automation played a key role in transforming operations, from material handling to precision assembly. Autonomous mobile robots (AMRs) were deployed to transport raw materials and finished goods across different sections of the facility, reducing reliance on manual labor and improving workflow efficiency. These AMRs leveraged real-time sensor data to navigate busy production floors safely, avoiding obstacles and adjusting their routes dynamically.

In addition to AMRs, robotic arms were integrated into the assembly process to handle delicate and repetitive tasks with precision. These robots were instrumental in increasing throughput and maintaining consistent quality standards, particularly in areas where human workers previously faced challenges due to precision requirements or environmental hazards.

The factory’s operations took place in an environment with extreme temperatures, high levels of dust, and constant vibrations from heavy machinery. Standard computing systems struggled to perform reliably under these conditions, leading to frequent failures and disruptions. VIA Intelligent Edge solutions were able to provide the necessary durability and real-time processing power. With industrial-grade components and fanless designs, these systems ensured uninterrupted operations, supporting AI-driven robotics while minimizing downtime and maintenance needs.

Powering the Future of Automation

At the core of these automation advancements were two NVIDIA-powered Edge AI PCs. These fanless, compact edge computing solutions are designed to handle the demanding workloads of industrial robotics, machine vision, and AI-driven automation.

VIA AMOS-9000: Featuring the NVIDIA Jetson Orin Nano processor, the AMOS-9000 delivers up to 40 TOPS of AI performance. This ruggedized system supports seamless integration with machine vision cameras, sensors, and other automation equipment through its extensive I/O options, including dual Gigabit Ethernet and COM ports. With a compact, fanless design, it excels in edge processing for real-time defect detection and quality control, ensuring reliable performance even in challenging industrial environments.

VIA AMOS-9100: Powered by the NVIDIA Jetson Orin NX processor, the AMOS-9100 delivers up to 70 TOPS of AI performance, making it ideal for advanced AI inferencing and robotics applications. It supports NVIDIA JetPack SDK for seamless deep learning model deployment and features integrated LoRa connectivity for reliable long-range, low-power communication. With its dual Gigabit Ethernet, PoE support, and a wide range of operating temperatures, the AMOS-9100 is built to handle complex industrial tasks in harsh environments.

These systems are purpose-built to operate reliably in the toughest industrial settings, utilizing industrial-grade components to endure high temperatures, dust, and vibration. Their streamlined form factor and advanced thermal management ensure efficient performance in constrained or challenging environments without compromising on computational power.

Explore VIA’s Edge Solutions

As factory automation continues to evolve, having the right computing solutions is essential for staying competitive. The VIA AMOS-9000 and AMOS-9100 provide the performance, reliability, and scalability needed to support advanced robotics, machine vision, and AI-driven automation.

Discover how the VIA AMOS-9100 and AMOS-9000 can redefine your factory’s automation capabilities. Visit their product pages to explore detailed specifications, browse VIA’s comprehensive range of Intelligent Edge solutions, or get in touch with our team to discuss how we can help you achieve your automation goals.