The factory floor is bustling as workers in hard hats and reflective vests start their shifts. Among them is a constant guardian— the VIA VAB-5000, a compact, powerful device being used to keep everyone safe. Stationed near work areas, it uses AI to monitor safety gear compliance, checking in real time that every worker has the required equipment and proper safety attire.

The Unseen Safety Inspector

The VAB-5000 acts as a vigilant safety inspector, ensuring that essential protective gear like helmets, vests, and belts is always worn correctly. This real-time monitoring is powered by advanced AI capabilities, allowing the system to operate seamlessly alongside workers without disrupting their workflow. Each component of this AI system— including skeleton detection, object detection, and human recognition—plays a unique role in maintaining safety standards on the factory floor.

Skeleton detection is used to monitor posture and movements, allowing systems to analyze body positioning and verify that protective gear is correctly worn according to job function. Object detection can identify specific safety items, like helmets, vests, and belts, ensuring essential equipment is present and securely positioned. Additionally, human recognition enables systems to differentiate between operators, supporting tailored safety checks based on individual roles. Together, these AI capabilities illustrate how the VAB-5000’s hardware could help maintain consistent safety standards across a workforce when customized for specific job requirements.

If anything is out of place—a loose belt, an unfastened helmet, or a misaligned vest—the VAB-5000 immediately sends an alert, allowing for quick adjustments and helping ensure everyone’s safety.

A Small Device with Big Capabilities

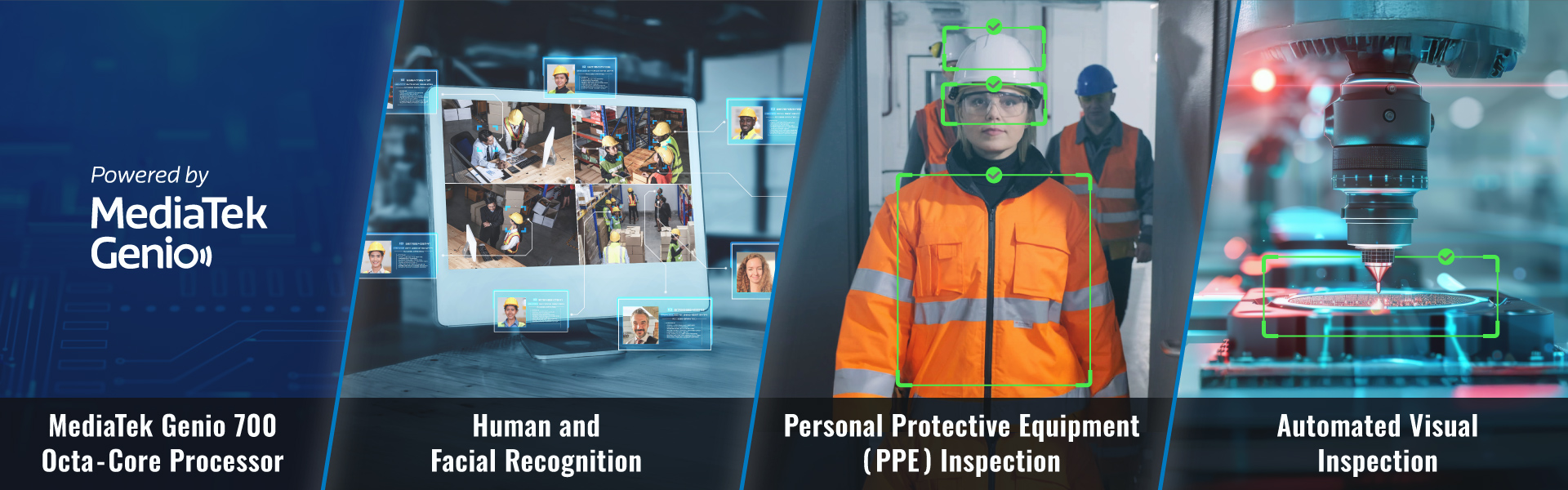

Despite its compact size, the VAB-5000 is built to handle the demands of industrial safety monitoring. Powered by the MediaTek Genio 700 processor, it can run multiple AI models simultaneously, delivering rapid analysis and real-time alerts. Its versatile I/O options, including support for high-definition MIPI CSI cameras and HDMI output, allow it to integrate seamlessly into existing safety systems and provide clear visual data for monitoring.

Real-Time Compliance without Disruption

The beauty of the VAB-5000 is its ability to operate multiple AI models simultaneously, ensuring continuous safety checks without disrupting workflow. Workers don’t have to pause for manual inspections, and supervisors can rely on the VAB-5000’s real-time monitoring to maintain compliance. It’s like having an extra set of eyes that never gets tired, making sure everyone is fully equipped throughout the day.

A Safer Future with AI

The VIA VAB-5000 represents a new era in workplace safety. By bringing together advanced AI with the processing power of the MediaTek Genio 700, it allows companies to uphold the highest safety standards with minimal effort. This innovative solution not only boosts compliance but also offers peace of mind, knowing that every worker has an intelligent system looking out for their well-being every step of the way.

For more information on the VIA VAB-5000, visit the product page, download the datasheet, or contact us.